Components and Specifications

Components and Specifications

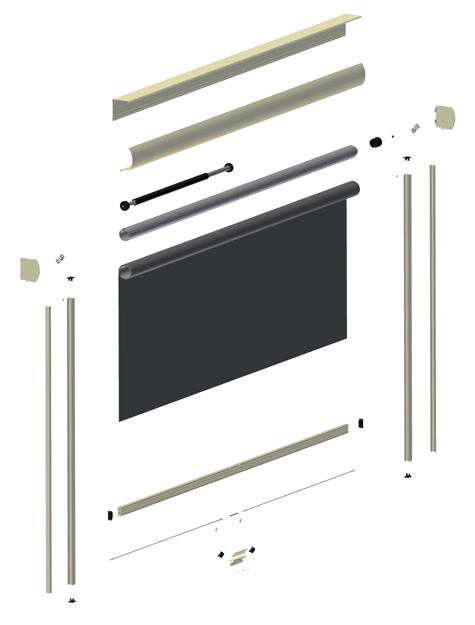

Headbox back

Headbox front

End plate

Channel

Side Track

Bottom Bar Assembly

Ezylift Latch

Axle Assembly

Spring

Skin

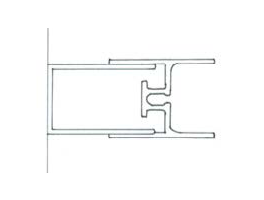

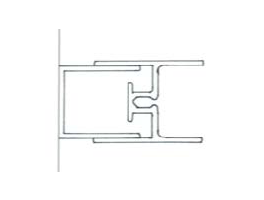

- Our tracking system is a patented extrusion, engineered to restrain outdoor blind skins with welded splines.

- The channel runs inside the track gives the cleaner finish which avoid ugly tracking effect

- Concealing the spline within the tracks and hiding the weld from view when installed.

Brackets & Channels

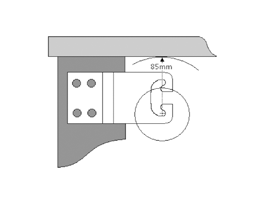

BRACKETS

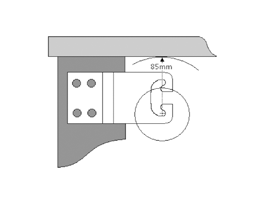

Brackets are available to support the top tube in situations where boxing is not suitable.

The top tube locators can be dropped into the brackets, which must be fitted to allow enough room for the fabric to build up around the roll.

It is important to consider when selling brackets without boxing that, when the skin is rolled down, there is an open gap left above the top tube.

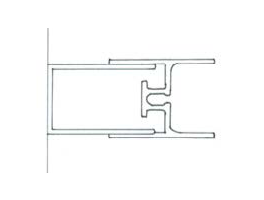

EXTRA DEEP (GEARBOX) CHANNEL

21mm deeper than standard. Developed to accommodate the extra width of a gearbox

Brackets & Channels

BRACKETS

Brackets are available to support the top tube in situations where boxing is not suitable.

The top tube locators can be dropped into the brackets, which must be fitted to allow enough room for the fabric to build up around the roll.

It is important to consider when selling brackets without boxing that, when the skin is rolled down, there is an open gap left above the top tube.

EXTRA DEEP (GEARBOX) CHANNEL

21mm deeper than standard. Developed to accommodate the extra width of a gearbox

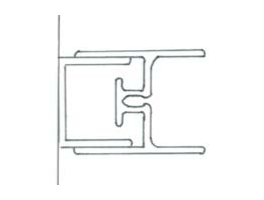

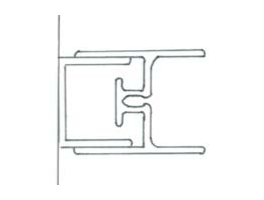

STANDARD CHANNEL

The most commonly used channel, at 23mm deep, you simply fix the channel to the application surface & sit tracks in place.

Each channel has +/- 5mm built-in adjustment. When happy with the blind’s operation, fix track to channel. If surface is square and measured correctly, there should be 5mm of channel visible when looking at the front of the blind.

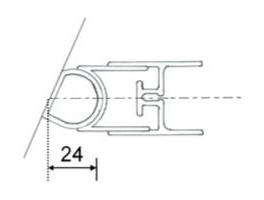

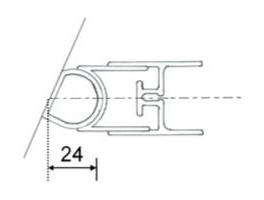

ANGLED CHANNEL

For fixing to angled surfaces. Measure using the fabric as your line to the wall (dotted centre line in diagram).

Drill a pilot, then a 13mm diameter hole in the flat tube for your driver to fit through. Mount to wall. Place the curved channel over the top, (covering the 13mm holes.) Adjust to required angle and fix to flat tube with rivets or size 10-16x16mm tek screws.

STANDARD CHANNEL

The most commonly used channel, at 23mm deep, you simply fix the channel to the application surface & sit tracks in place.

Each channel has +/- 5mm built-in adjustment. When happy with the blind’s operation, fix track to channel. If surface is square and measured correctly, there should be 5mm of channel visible when looking at the front of the blind.

ANGLED CHANNEL

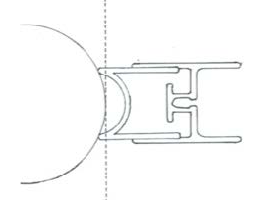

For fixing to angled surfaces. Measure using the fabric as your line to the wall (dotted centre line in diagram).

Drill a pilot, then a 13mm diameter hole in the flat tube for your driver to fit through. Mount to wall. Place the curved channel over the top, (covering the 13mm holes.) Adjust to required angle and fix to flat tube with rivets or size 10-16x16mm tek screws.

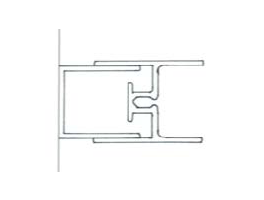

DEEP CHANNEL

Deep channels are 10mm deeper than standard. Installation method is exactly the same – this channel is simply an option to use for neatly overcoming protruding bricks or copper piping.

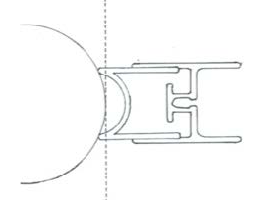

SMALL COLUMN CHANNEL (OR CURVED CHANNEL)

For fixing to columns smaller than 200mm. For larger diameter columns a standard channel can be used. Simply fix to column, taking care not to over-tighten, as this may bend the channel edges out of shape.

DEEP CHANNEL

Deep channels are 10mm deeper than standard. Installation method is exactly the same – this channel is simply an option to use for neatly overcoming protruding bricks or copper piping.

SMALL COLUMN CHANNEL (OR CURVED CHANNEL)

For fixing to columns smaller than 200mm. For larger diameter columns a standard channel can be used. Simply fix to column, taking care not to over-tighten, as this may bend the channel edges out of shape.

TECHNICAL SPECIFICATIONS

Maximum Width | 5500mm

Maximum Height | 3000mm

Maximum Area | (m2) 16.5

Headbox Size | 145mm x 150mm high

Bottom Bar Size | 25mm x 70mm wide

Control Options | Spring, Crank or 12v Motorised

Operation Control

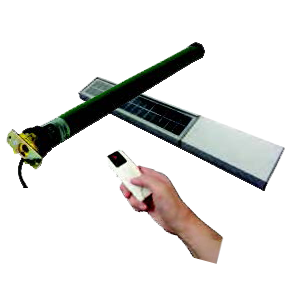

Motorised

-

The E-SolarPRO is a sleek module which collects energy from the sun through the solar panel andstores it in the battery located in one end of the module. Using an Ozroll E-Trans Remote, the stored energy operates the ODS T-Series 12v motor with the press of a button. The E-SolarPRO offers a standalone motorised system without a need for mains power.

* E-SolarPRO must be fixed in a position where direct sunlight can be received.

The E-Port 18650 Standard or RF controls with the T-Series motors are another stand alone option for controlling the Slidetrack Window Blinds and Verandah Screens. As with the E SolarPRO an electrician is NOT required for installation and the motors are driven by the power from the Lithium-Ion batteries in the controls. The E-Port 18650 RF control works with a 1 or 9 channel hand-held remote.

Hardwired 240v Electric motors are available in either standard with a fixed wall switch or an RTS version operated by a 1ch or 5ch handheld remote.

Manual

SPRING ASSIST WITH EZYLIFT

The manual Spring Assist option is a common choice for Outdoor Blinds across Australia, however Slidetrack's unique Ezylift handle design provides premium strength with effortless operation.

GEARBOX

Gearbox operation is a traditional system, whereby the user manually raises the blind with a cranks handle which hooks into an eye outlet. This type of control must be fitted with extra deep channels.

SPRING WITH BOLTS ON THE BOTTOM BAR

Boxing Options

| Box Type | Maximum Height Motorised or Gearbox | Maximum Height Motorised or Gearbox | Maximum Height Manual | Maximum Height Manual |

|---|---|---|---|---|

| MESH | PVC | MESH | PVC | |

| 145 Extruded | 3200 | 3100 | 3100 | 3000 |

| 150 Roll Formed | 3500 | 3300 | 3300 | 3200 |

| Mounted In Brackets | 3500 | 3500 | 3500 | 3500 |

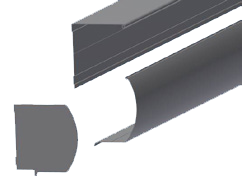

- It is extruded head box is a two-piece pelmet produced with cast aluminium and finished with specialist end caps.

- This fully enclosed head box offers a unique smooth shape

- Industry leading strength due to thickness of material. Tested on blinds as wide as 6600mm, this is the ideal option for wide spans or for powder coating, when trying to avoid warping or bowing.

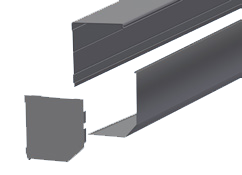

- We use well engineered roll formed head box is a two-piece pelmet in our blinds

- Ozroll’s square roller shutter end plates have been adapted to support the Unique Slidetrack top tube

- The fully enclosed head box which protects the rolled up skin, option offers a conventional look at a cost effective price.